Media

The 2025 “Safety Production Month” activities at Tianqi Lithium concluded successfully, themed “Everyone Talks Safety, Everyone Masters Emergency Response — Identifying Safety Hazards Around Us.” The company's headquarters, various bases, projects, and Tianqi Lithium Innovation Experimental Institute all participated comprehensively. Through a diverse and multi-level series of events, the activities effectively enhanced employees' safety awareness and emergency response capabilities, reinforcing the concept of safe production.

The “Safety Production Month” series officially launched on May 27, utilizing a multi-dimensional promotional matrix of offline posters and banners combined with online interactive activities. This created a strong atmosphere around the campaign, motivating active participation from all employees and firmly strengthening the EHS defense line. All bases and projects responded simultaneously through both offline and online channels, marking the full commencement of Safety Production Month.

Safety Knowledge Challenge Competition

Following the successful completion of the 2024 Safety Knowledge Competition, the 2025 edition took it a step further, with an expanded and upgraded question bank, attracting 1,218 participants from various bases, projects, and research institutes. Contestants competed fiercely, deepening their understanding of safety knowledge through the competition.

Safety Production Micro Video Shooting Competition

The Micro Video Shooting Competition focused on the theme of “Safety Production Red Line Prohibitions,” vividly showcasing scenes of risk prevention, hazard elimination, and emergency rescue from the creators' perspective. The competition aimed to strengthen safety awareness across the organization. A total of 49 works were submitted, covering common safety hazards at production sites.

Safety Fun Activities

Tianqi Lithium's headquarters organized Safety Fun Activities, including offline safety knowledge challenges, hazard detection with a keen eye, and safety standard bean bag toss, among others. These activities aimed to reinforce employees' memory and understanding of safety knowledge through a fun and engaging approach.

Meanwhile, various bases and projects actively responded by leveraging the opportunity of Safety Production Month to organize unique and innovative activities. All employees participated in hands-on exercises, effectively enhancing their safety production capabilities.

Chongqing Base

The Chongqing Base strengthened employee safety awareness through the daily “3-Minute Safety” pledge ceremony. Additionally, the “Safety Microscope” hazard inspection activity was conducted to improve employees' ability to anticipate and identify risks. Furthermore, the “Family Bond” initiative was launched, inviting employees' family members to participate in safety-themed artwork and video creation. This initiative aimed to build a “company-employee-family” safety network, enhancing the safety responsibility of all employees.

Zhangjiagang Base

The head of the Zhangjiagang Base took the lead in signing the safety commitment letter and organized CPR training, SCBA (Self-Contained Breathing Apparatus) practical competitions, and offline safety knowledge contests. The SCBA practical competition effectively tested and enhanced the emergency responders' proficiency in operating equipment, laying a solid foundation for the establishment of a professional emergency rescue team.

Shehong Base

Shehong Base organized a series of safety-related activities, including expert lectures, safety knowledge quizzes, and a themed speech contest, attracting participation from more than 600 employees. The “Building a Safety Line Together” speech contest provided a platform for employees to share real-life safety cases, effectively promoting key safety values. The initiative played a vital role in reinforcing the company's safety culture and raising collective risk prevention awareness.

Anju Base

Anju Base organized a firefighting rescue drill and a first aid skills competition, with experts from the Red Cross specially invited to provide on-site guidance. Through these competitive activities, employees enhanced their practical emergency response capabilities, strengthened overall preparedness, and vividly demonstrated the company’s commitment to a strong safety culture.

Yanting Base

Focusing on summer flood prevention and earthquake response, Yanting Base conducted practical emergency drills to strengthen employees' ability to handle natural disasters. An innovative “one-on-one” Q&A mechanism was also introduced during pre-shift meetings to assess employees' grasp of safety knowledge. This approach ensures that safety awareness is deeply instilled across the workforce, reinforcing the foundation for safe and stable operations.

Shenghe Base

Shenghe Base has set up a “Safety Production Reading Corner” to encourage employees to study safety-related materials and enhance their knowledge. In addition, a Safety Awareness and Consultation Day was organized, where on-site interactive Q&A sessions were held to address employees' practical challenges in workplace safety. These efforts have effectively improved overall safety knowledge and strengthened the safety awareness of all staff.

Tianqi Lithium Innovation Experimental Institute

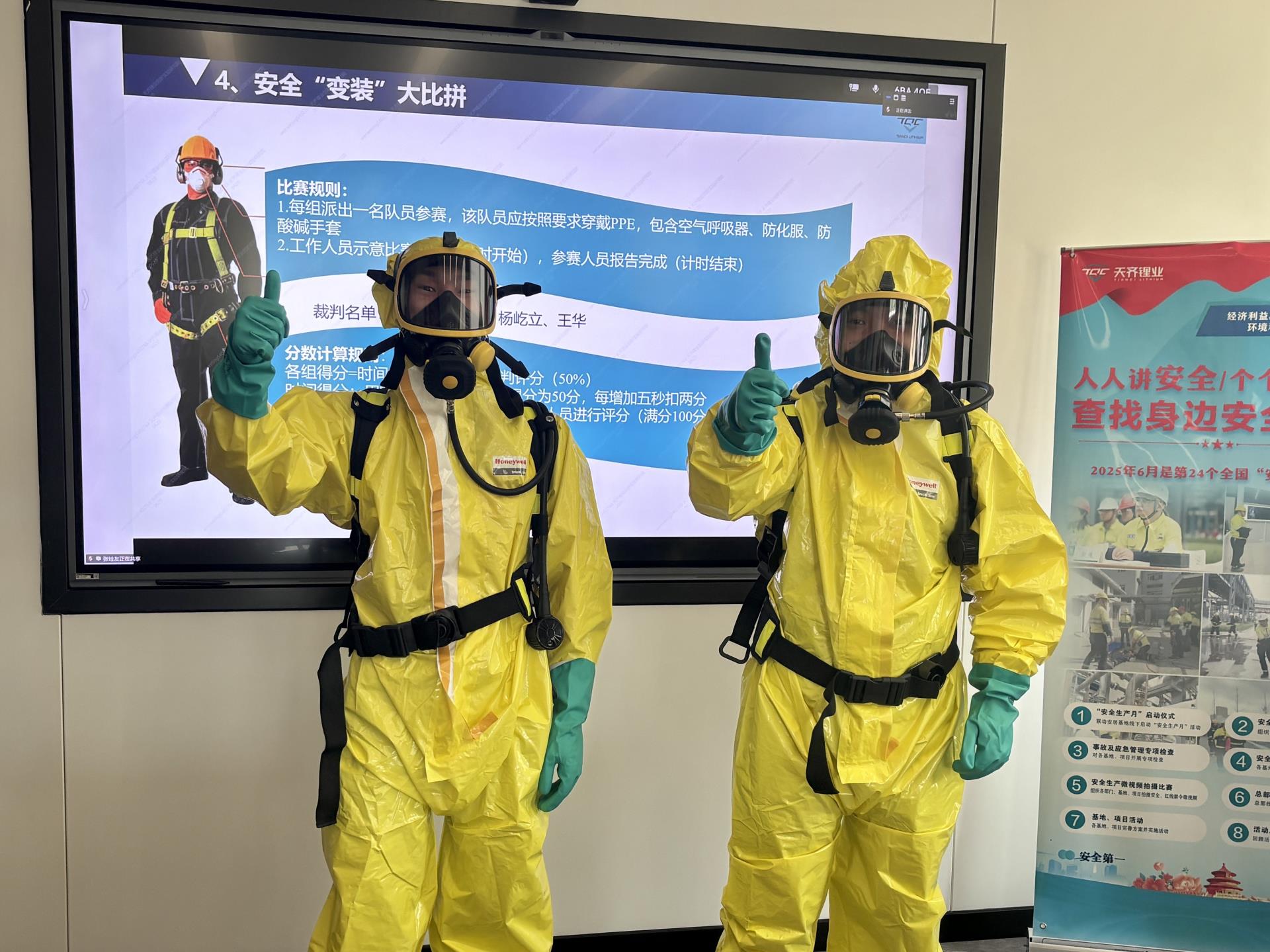

The Tianqi Lithium Innovation Experimental Institute held its first-ever Workplace Safety Month. A Safety Committee was officially established, and a series of safety skill competitions were organized to promote practical awareness. Creative and engaging activities such as “Spot the Safety Hazards” and “Safety Dress-Up Challenge” helped create a fun, interactive atmosphere where everyone is encouraged to “prioritize safety.”These efforts laid a solid foundation for ensuring the safe and orderly progress of research and development work.

Chongqing 1,000-Ton Lithium Metal and Supporting Raw Materials Project

The Chongqing 1,000-Ton Project has adopted a closed-loop safety management model based on the cycle of “Training – Inspection – Rectification – Incentive.” Key initiatives include training sessions on hazard identification, special rectification campaigns targeting mechanical equipment, and hands-on emergency drills. The project also encourages employees to proactively report potential hazards, further strengthening on-site safety management and fostering a culture of accountability.

Jiangsu 30,000-Ton Project

To address challenges in contractor management, the Jiangsu 30,000-Ton Project has implemented a series of targeted safety measures. A hazard log is updated daily, underperforming contractors are interviewed weekly regarding delayed rectifications, and a monthly safety ranking is published. These actions drive contractors to strictly fulfill their safety responsibilities, ensuring the project advances safely and efficiently.

The 2025 Workplace Safety Month activities have successfully concluded, but the work of ensuring safety is never-ending. Tianqi Lithium will continue to uphold high standards and strict requirements to build a long-term safety management system. By deeply embedding safety awareness in every employee’s heart, the company aims to maintain a consistently stable and safe environment, guaranteeing high-quality development.